Educação

| Mechanochemistry applied to the synthesis of 2-phenylimidazo[1,2-α]pyridine as a teaching tool for green chemistry |

|

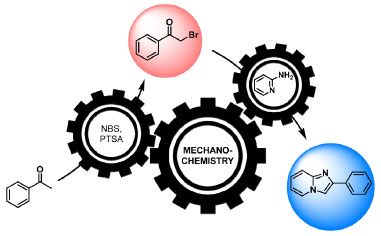

José S. S. Neto Instituto de Química, Universidade Federal de Goiás, 74690-900 Goiânia - GO, Brasil Received: 01/02/2024 *e-mail: lucianoliao@ufg.br; felipecoelho@ufg.br In the present work, we developed an experimental class for undergraduate students concerning the linear synthesis of 2-phenylimidazo[1,2-α]pyridine through mechanochemical techniques. This approach aims to conceptualize the green chemistry principles through a safe, robust, atom-economic, energy-efficient, and solvent-free method for preparing these classes of compounds by manual grinding and vortex mixing. The methodology was easily applied in experimental classes for chemistry students and could be easily expanded to other courses such as pharmacy and biotechnology. INTRODUCTION In recent years, sustainable development has emerged as an important concept for preserving the environment and society. In contrast, for many years, the chemical industry was considered a major polluter of the environment due to its generation of hazardous waste that, when treated improperly, constitutes a great danger to life. In this sense, starting in the 1990s, some attitudes and treaties were initiated to reduce the generation of chemical residues in all production lines.1 These attitudes culminated in 1998 with the release of the book by Anastas and Warner2 entitled "Green Chemistry: Theory and Practice", which shows a series of attitudes to be followed for sustainable development in green chemistry. From there, a perfect green chemical process is guided by a series of procedures called the 12 principles of green chemistry, which are (i) waste prevention, (ii) atom economy, (iii) less hazardous chemical synthesis, (iv) designing safer chemicals, (v) safer solvents and auxiliaries, (vi) design for energy efficiency, (vii) use of renewable feedstocks, (viii) reduce derivatives, (ix) catalysis, (x) design for degradation, (xi) real-time pollution prevention and (xii) safer chemistry for accident prevention.3 Many of these principles are found in mechanochemistry, which arises as a sustainable alternative for organic synthesis. This technique is based on the use of mechanical friction (mechanical energy) as a way to make contact between molecules and consequently promote a chemical reaction.4 Originated in prehistory, where mechanical energy was used to create fire and grind grains and food, it was initially adapted to chemical procedures with a mortar and pestle. It currently has equipment dedicated to this purpose. Regarding the use of mechanochemistry in organic synthesis, it is an important sustainable chemical tool since it has several advantages: it does not require the use of solvents, there is a decrease in reaction time and formation of waste compared to traditional methods; in some cases, it improves the reaction yield.4,5 Bringing these principles of green chemistry and alternative synthetic methodologies to an educational context is critical. In this sense, experimental classes play a vital role in learning. The experimental procedures bridge the gap between theory and practice, inspire curiosity, enhance critical thinking, promote teamwork, and connect scientific concepts to the real world. These classes not only help students understand complex concepts but also develop a lifelong love of science and prepare them for future challenges. Therefore, they are an indispensable tool in modern education.6 With this in mind, the present work describes an experimental class that stimulates thinking in sustainable chemistry (green chemistry) and alternative synthetic protocols through the mechanochemical preparation of 2-phenylimidazo[1,2-a]pyridine. The approach was performed for both 2-bromoacetophenone starting material and desired imidazo[1,2-a]pyridine. Additionally, two mechanochemical techniques for organic synthesis are presented, which are manual grinding and the use of spheres in a vortex mixer, as depicted in Scheme 1, both easily applicable in teaching laboratories.

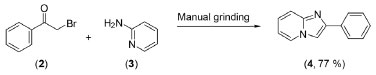

Scheme 1. General synthetic pathway

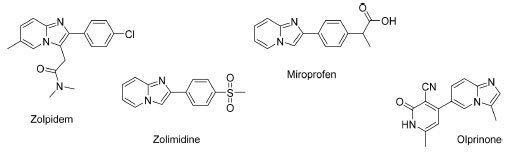

Theoretical aspects The imidazo[1,2-a]pyridines are characterized by the junction of two heterocyclic nuclei in their structure: imidazole and pyridine. This heterocycle was described for the first time in 1925 by Tachitschibabim,7 and for a long time, this class of compounds was little studied due to the lack of efficient methods for their synthesis. However, in recent decades, a series of methodologies, particularly those catalyzed by metal, have made it possible to synthesize imidazo[1,2-a]pyridines.8 From then on, a series of applications for this compound class was described, emphasizing the pharmacological area. This is depicted in Figure 1, where the structural unit can be found in zolpidem, used to treat insomnia; zolimidine, used for peptic ulcers and gastroesophageal reflux disease; miroprofen, sold as an analgesic and anti-inflammatory, and olprinone, which is a cardiotonic agent.9

Figure 1. Imidazo[1,2-a]pyridine skeleton in commercial drugs

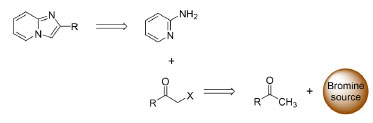

Due to the importance of this class of compounds, several methodologies are described for the synthesis of imidazo[1,2-a]pyridines. One of the most versatile ways present in the literature10 to obtain this compound is through the use of 2-aminopyridines and α-haloketones as starting substrates, as presented in Scheme 2.

Scheme 2. Retrosynthetic analysis of imidazo[1,2-a]pyridines

In turn, α-haloketones are prepared by ketone α-bromination, a reaction in which a bromine moiety (-Br) is added to the carbon directly linked to the carbonyl group (C=O). The introduction of bromine at the alpha position is an essential step in the synthesis of many organic compounds because it creates a reactive chemical function that can be used in subsequent reactions.11 The most classic and well-known methodology for α-bromination of ketones is to use molecular bromine (Br2) under acid catalysis. However, this methodology may present some selectivity problems, with dibromination of the alpha position of the ketone and bromination of other positions of the starting substrate, also known as overbromination.12 Thus, among the existing α-bromination methods, N-bromosuccinimide (NBS) is highlighted as a bromine source being a versatile tool for bromination reactions since NBS is a reagent that allows more specific and economical control over the addition of bromine to alpha carbons.13,14 Furthermore, NBS is a solid reagent, easy to handle, highly available, and can be easily used in chemical methodologies, such as mechanochemistry. In this way, both steps of preparation of 2-bromoacetophenone starting material and 2-phenylimidazo[1,2-α]pyridine product can be carried out in a mechanochemical procedure.

RESULTS AND DISCUSSION The mechanochemical experiment was completed by 32 third-year undergraduate chemistry students, who worked in groups of two, performing both steps of preparation and purification of 2-bromoacetophenone and synthesis of 2-phenylimidazo[1,2-a]pyridine in a single class of 4 h. In manual grinding, every 10 min, the two team members alternate in the grinding process. The product was allowed to dry under air for over a week. Then, the reaction yield was calculated, the melting point was determined, and spectroscopic characterization (1H NMR, 13C NMR, and FTIR) was performed. The α-bromination of acetophenone is usually carried out with N-bromosuccinimide (1 equiv.) and p-toluenesulfonic acid (1 equiv.) under reflux for 12 h.14 It is worth mentioning that the mechanochemical version of this procedure has not been reported. Thus, this procedure was optimized and validated before being implemented in class. After a brief reaction optimization, which involved adjusting the manual grinding time and the amount of p-toluenesulfonic acid, acetophenone (1) was successfully converted to 2-bromoacetophenone (2) in a satisfactory yield of 96% after 30 min of grinding, as depicted in Scheme 3. This preliminary investigation is discussed in the theoretical introduction of the experimental class as a practical example of developing a greener procedure, wherein the solvent was eliminated, and the reaction time was reduced.

Scheme 3. Synthesis of 2-bromoacetophenone through manual grinding

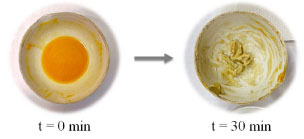

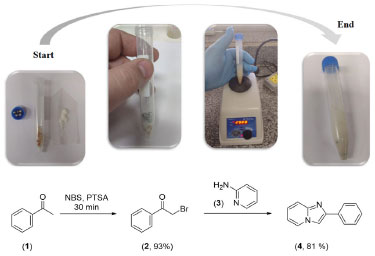

In this way, the students performed a gram-scale mechanochemical synthesis of 2-bromoacetophenone employing the optimized reaction conditions. The protocol can be executed with both a mortar and a pestle or a thick wall (4 mm) test tube and a glass rod. The N-bromosuccinimide, used without purification as a brown solid, served as an indicator of reaction progress, as the mixture changed from an initial brown hue to a pale-yellow color in the conclusion of the process. Furthermore, due to the relatively low melting point of 2-bromoacetophenone (48-51 ºC), the reaction mixture gradually turned pasty over time, as depicted in Figure 2.

Figure 2. Physical aspects of mechanochemical reaction

After the reaction was completed, the mixture was dissolved in ethyl acetate and washed with aqueous sodium thiosulfate and aqueous sodium bicarbonate to remove the remaining NBS and acid catalyst, respectively. The product was allowed to dry under air for over a week. Then, the reaction yield was calculated, the melting point was determined, and spectroscopic characterization (1H NMR, 13C NMR, and FTIR) was performed. The 2-bromoacetophenone was obtained with an average yield of 96% and a range of 90-99%. Besides the spectroscopic characterization, the students were encouraged to evaluate the purity of the compounds by thin-layer chromatography. As both acetophenone and 2-bromoacetophenone have the same Rf values, visualization reagents were used to observe the chemical transformation through the different colors that appeared, and the limitations of the technique were discussed. In the sequence, the second step involved the reaction of 2-bromoacetophenone (2) with 2-aminopyridine (3), as depicted in Scheme 4. The same procedure was performed with manual grinding for 30 min. The resulting solid was dissolved in hot acetone (15 mL), cooled in an ice bath, and added cold hexane (50 mL) to promote the product precipitation. After filtration, the 2-phenylimidazo[1,2-a]pyridine (4) was obtained in an average yield of 77% in a 40-81% range. The variation in reaction yield observed in the groups was related to the amount of hot acetone (or ethyl acetate) added to dissolve the reaction mixture. Excess of the polar solvent is detrimental to product precipitation.

Scheme 4. Mechanochemical synthesis of 2-phenylimidazo[1,2-a]pyridine

The students measured the melting point of the precipitate, obtaining an average value of 135 ± 3.0 ºC, which is in agreement with 2-phenylimidazo[1,2-a]pyridine. The spectroscopic data confirmed the structure of the product of interest. These data can be found in the Supplementary Material section. Additionally, with the successful preparation of compounds 2 and 4 using manual grinding, the protocol was modernized by incorporating a ball mill apparatus, as presented in Scheme 5. After adding the starting substrates and some steel spheres to a plastic falcon-type tube, it was sealed and placed under agitation in a laboratory vortex for 10 min. This resulted in the products of interest with yields similar to those obtained through manual grinding, as depicted in Figure 2. This experiment was demonstrative, aiming to compare the results obtained through vortex mixing with that obtained by the students with the manual grinding.

Scheme 5. Ball milling approach in the 2-phenylimidazo[1,2-a]pyridine mechanosynthesis

Finally, as the experimental procedures concluded, the concepts of green chemistry discussed throughout the course were highlighted, along with the theoretical aspects of α-carbonyl substitution and condensation reactions in organic synthesis. The students were challenged to present the reaction mechanisms involved, as well as to analyze the characterization data.

CONCLUSIONS In summary, the implemented experimental class allows the students to have a better understanding of green chemistry concepts, performing an environmentally friendly methodology using mechanochemistry in synthesizing 2-bromoacetophenone and 2-phenylimidazo[1,2-a]pyridine. This methodology is easily, accessible, cheap, robust, and leads to the formation of expected products at high yields.

EXPERIMENTAL Materials and methods Starting materials obtained from commercial suppliers were used unless otherwise stated. The manual grinding procedure was carried out with a mortar and a pestle. The vortex mixing procedure was performed with a 5 mL falcon-type tube charged with 3 steel spheres of approximately 4.0 mm of diameter in a digital vortex mixer iSwix VT (Neuation, Gujarat, India). 1H and 13C NMR spectra were acquired on a Bruker Avance III 500 NMR spectrometer (Rheinstetten, Germany) operating at 11.75 Tesla, fitted with a broadband inverse (BBI) probe at 25 ºC. The deuterated chloroform (CDCl3) was used as the solvent. The spectra were processed using the Bruker TopSpin software. 1H and 13C chemical shifts are given in δ (ppm) related to the tetramethylsilane (TMS) signal at δ 0.00 as an internal reference. Spectra in the infrared region were obtained in the form of a KBr disc on a Spectrum 400 equipment (PerkinElmer, Shelton, USA). Mechanochemical synthesis of 2-bromoacetophenone through manual grinding In the mortar, N-bromosuccinimide (2.0 g, 11.25 mmol), acetophenone (1.2 mL, 10.0 mmol) and p-toluenesulfonic acid (1.9 g, 11.0 mmol) were added. The mixture was ground with the pestle for 30 min. The mixture was diluted in 25 mL of ethyl acetate (EtOAc), washed with 1 mol L-1 sodium thiosulfate solution (1 × 20 mL), 1 mol L-1 sodium bicarbonate solution (1 × 20 mL), and deionized water (1 × 20 mL). The organic phase was dried with sodium sulfate (Na2SO4), and the solvent was removed in a rotary evaporator to afford pure 2-bromoacetophenone in 96% yield. Mechanochemical synthesis of 2-bromoacetophenone through vortex mixing In a falcon-type charged with steel spheres, N-bromosuccinimide (2.0 g, 11.25 mmol), acetophenone (1.2 mL, 10.0 mmol), and p-toluenesulfonic acid (1.9 g, 11.0 mmol) were added. The tube was sealed and submitted to 700 rpm in a vortex for 10 min. After this, the reaction mixture was diluted in 25 mL of EtOAc, extracted with 1 mol L-1 sodium thiosulfate solution (1 × 20 mL), 1 mol L-1 sodium bicarbonate solution (1 × 20 mL), and deionized water (1 × 20 mL). The organic phase was dried with Na2SO4, and the solvent was removed in a rotary evaporator. Mechanochemical synthesis of 2-phenylimidazo[1,2-α]pyridine through manual grinding In a mortar, 2-bromoacetophenone (1.10 g, 5.5 mmol) and 2-aminopyridine (0.5 g, 5.3 mmol) were added and ground with the pestle for 30 min. Then, the mixture was diluted in 15.0 mL of hot EtOAc or acetone in a 100 mL beaker and cooled in an ice bath. After adding 50 mL of ice-cold hexane, the precipitated 2-phenylimidazo[1,2-α]pyridine was filtered under vacuum, affording 4 in 77% yield without further purification. Mechanochemical synthesis of 2-phenylimidazo[1,2-α]pyridine through vortex mixing 2-Bromoacetophenone (1.10 g, 5.5 mmol) and 2-aminopyridine (0.5 g, 5.3 mmol) were added in a falcon-type charged with steel spheres. The tube was sealed and stirred at 700 rpm in a vortex for 10 min. The mixture was diluted in 15.0 mL of hot EtOAc or acetone and transferred to a 100 mL beaker. Then, 50 mL of ice-cold hexane was added, and the precipitated 2-phenylimidazo[1,2-α]pyridine was filtered under a vacuum.

SUPPLEMENTARY MATERIAL Images of the steps of the mechanochemical reactions, 1H, 13C NMR, and IR spectra, data of the compounds are described in the supplementary material, available at http://quimicanova.sbq.org.br/, as a PDF file, with free access.

ACKNOWLEDGMENTS The authors would like to thanks to CNPq, CAPES, FAPEG and FUNAPE-UFG for financial support.

REFERENCES 1. Tundo, P.; Anastas, P. T.; Black, D. S.; Breen, J.; Collins, T.; Memoli, S.; Miyamoto, J.; Polyakoff, M.; Tumas, W.; Pure Appl. Chem. 2000, 72, 1207 [Crossref]; Sanseverino, A. M.; Quim. Nova 2000, 23, 102. [Crossref] 2. Anastas, P. T.; Warner, J.; Green Chemistry: Theory and Practice, illustrated ed.; Oxford University Press: Oxford, 1998. 3. Valderrama, C. J. M.; Huamán, H. I. M.; Valencia-Arias, A.; Coronado, M. H. V.; Cardona-Acevedo, S.; Delgado-Caramutt, J.; Sustainability 2023, 15, 13946 [Crossref]; Anastas, P. T.; Eghbali, N.; Chem. Soc. Rev. 2010, 39, 301 [Crossref]; Horvath, T. I.; Anastas, P. T.; Chem. Rev. 2007, 107, 2169 [Crossref]; Lenardão, E. J.; Freitag, R. A.; Dabdoub, M. J.; Batista, A. C. F.; Silveira, C. C.; Quim. Nova 2003, 26, 123. [Crossref] 4. Liu, X.; Li, Y.; Zeng, L.; Li, X.; Chen, N.; Bai, S.; He, H.; Wang, Q.; Zhang, C.; Adv. Mater. 2022, 34, 2108327 [Crossref]; Do, J. L.; Frisčić, T.; ACS Cent. Sci. 2017, 3, 13 [Crossref]; Wixtrom, A.; Buhler, J.; Abdel-Fattah, T.; J. Chem. Educ. 2014, 91, 1232 [Crossref]; Berry, D. E.; Carrie, P.; Fawkes, K. L.; Rebner, B.; Xing, Y.; J. Chem. Educ. 2010, 87, 533. [Crossref] 5. Hernández, J. G.; Bolm, C.; J. Org. Chem. 2017, 82, 4007 [Crossref]; Tan, D.; Loots, L.; Frisčić, T.; Chem. Commun. 2016, 52, 7760 [Crossref]; Wang, G. W.; Chem. Soc. Rev. 2013, 42, 7668 [Crossref]; Takacs, L.; Chem. Soc. Rev. 2013, 42, 7649. [Crossref] 6. Santaniello, B. S.; Price, M. J.; Murray Junior, J. K.; J. Chem. Educ. 2017, 94, 388 [Crossref]; Costa, O. B. S.; Santana, L. L. B.; Cunha, S.; Quim. Nova 2015, 38, 874 [Crossref]; Cunha, S.; Lião, L. M.; Bonfim, R. R.; Bastos, R. M.; Monteiro, A. P. M.; Alencar, K. S.; Quim. Nova 2003, 26, 425 [Crossref]; Cunha, S.; Fontes, T.; Araujo, D. M.; Riatto, V. B.; Quim. Nova 2018, 41, 116. [Crossref] 7. Tschitschibabin, A. E.; Chem. Ber. 1925, 58, 1704. [Crossref] 8. Panda, J.; Raiguru, B. P.; Mishra, M.; Mohapatra, S.; Nayak, S.; ChemistrySelect 2022, 7, e202103987 [Crossref]; Kurteva, V.; ACSOmega 2021, 6, 35173 [Crossref]; Bagdi, A. K.; Santra, S.; Monir, K.; Hajra, A.; Chem. Commun. 2015, 51, 1555 [Crossref]; Shi, L.; Li, T.; Mei, G. J.; Green Synth. Catal. 2022, 3, 227. [Crossref] 9. Neto, J. S. S.; Balaguez, R. A.; Franco, M. S.; Machado, V. C. S.; Saba, S.; Rafique, J.; Galetto, F.; Braga, A. L.; Green Chem. 2020, 22, 3410 [Crossref]; Douhal, A.; Amat-Guerri, F.; Acuna, A. U.; Angew. Chem., Int. Ed. 1997, 36, 1514 [Crossref]; Yamada, Y.; Matsuo, S.; Abe, K.; Kubo, S.; Sato, S.; J. Mater. Sci. 2016, 51, 8900 [Crossref]; Vanda, D.; Zajdel, P.; Soural, M.; Eur. J. Med. Chem. 2019, 181, 111569 [Crossref]; Lv, K.; Li, L.; Wang, B.; Liu, M.; Wang, B.; Shen, W.; Guo, H.; Lu, Y.; Eur. J. Med. Chem. 2017, 137, 117 [Crossref]; Lefin, R.; van der Walt, M. M.; Milne, P. J.; Terre'blanche, G.; Bioorg. Med. Chem. Lett. 2017, 27, 3963. [Crossref] 10. Bagdi, A. K.; Rahman, M.; Santra, S.; Majee, A.; Hajra, A.; Adv. Synth. Catal. 2013, 355, 1741 [Crossref]; Zhu, D. J.; Chen, J. X.; Liu, M. C.; Dinga, J. C.; Wu, H. Y.; J. Braz. Chem. Soc. 2009, 20, 482 [Crossref]; Ponnala, S.; Kumar, S. T. V. S. K.; Bhat, B. A.; Sahu, D. P.; Synth. Commun. 2005, 35, 901 [Crossref]; Rival, Y.; Grassy, G.; Michel, G.; Chem. Pharm. Bull. 1992, 40, 1170 [Crossref]; Buu-Hoi, N. P.; Jacquignon, P.; Xuong, N. D.; Lavit, D.; J. Org. Chem. 1954, 19, 1370. [Crossref] 11. Liu, Z. C.; Wang, Z. Q.; Zhang, X.; Yin, L.; Nat. Commun. 2023, 14, 2187 [Crossref]; Hassan, A. Y.; Shabaan, S. N.; El-Sebaey, S. A.; Abou-Amra, E. S.; Sci. Rep. 2023, 13, 5585 [Crossref]; Matta, R.; Pochampally, J.; Dhoddi, B. N.; Bhookya, S.; Bitla, S.; Akkiraju, A. G.; BMC Chem. 2023, 17, 61 [Crossref]; Delost, M. D.; Njardarson, J. T.; Org. Lett. 2021, 23, 6121 [Crossref]; Guo, F. Y.; Zheng, C. J.; Wang, M.; Ai, J.; Han, L. Y.; Yang, L.; Lu, Y. F.; Yang, Y. X.; Piao, M. G.; Piao, H. R.; Jin, C. M.; Jin, C. H.; ChemMedChem 2021, 16, 2354 [Crossref]; Kawada, K.; Takahashi, I.; Arai, M.; Sasaki, Asami, T.; Yajima, S.; Ito, S. Y.; J. Agric. Food Chem. 2019, 67, 6143. [Crossref] 12. Guan, Y. X.; Zahra, A. M.; Huang, K. W.; Arabian J. Chem. 2015, 8, 892 [Crossref]; Salama, T. A.; Novak, Z.; Tetrahedron Lett. 2011, 52, 4026 [Crossref]; Langley, W. D.; Org. Synth. 1929, 9, 20. [Crossref] 13. Mohinuddin, P. K.; Reddy, B. M.; Reddy, G. T.; Reddy, N. C. G.; Org. Commun. 2015, 8, 60. [Crossref] 14. Feng, Q.; Zhang, J.; Luo, S.; Huang, Y.; Peng, Z.; Wang, G.; Eur. J. Med. Chem. 2023, 262, 115920 [Crossref]; Adhikari, M. V.; Samant, S. D.; Ultrason. Sonochem. 2011, 9, 107 [Crossref]; Lee, J. C.; Bae, Y. H.; Chang, S. K.; Bull. Korean Chem. Soc. 2003, 24, 407. [Crossref] |

On-line version ISSN 1678-7064 Printed version ISSN 0100-4042

Qu�mica Nova

Publica��es da Sociedade Brasileira de Qu�mica

Caixa Postal: 26037

05513-970 S�o Paulo - SP

Tel/Fax: +55.11.3032.2299/+55.11.3814.3602

Free access