Nota Técnica

| Inertization of small-scale chemical wastes using iron phosphate glass |

|

Joao P. GobboI; Dalva L. A. de FariaI,*; José R. MartinelliII

IInstituto de Química da Universidade de São Paulo, CP 26077, 05513-970 São Paulo - SP, Brasil Recebido em 25/06/2013 *e-mail: dlafaria@iq.usp.br The viability of small-scale heavy-metal waste immobilization into iron phosphate glasses was investigated. Several waste forms containing different amounts of heavy-ion wastes were evaluated (5%, 10%, 15%, 20%, 26%, 33%, 40% and 50% by mass) and their X-ray diffraction patterns revealed that no crystallization occurred in glasses with waste concentrations up to 26%. The dissolution rates for all of the reported glass compositions (ca. 10-8 g cm-2 min-1) are similar to those reported for the materials most commonly used for waste vitrification. Iron phosphate glasses thus proved to be very useful for the immobilization of heavy-metal wastes, exhibiting good contention and chemical durability comparable to that of borosilicate glasses. INTRODUCTION The immobilization of wastes that represent a risk to the environment or to public health avoids their dispersion in soil, in the atmosphere and in water bodies and reduces the waste volume. Glasses are an excellent option for such immobilization because, in general, they exhibit high chemical durability, slow dissolution rates in water, high mechanical resistance and high thermal stability; they have been investigated for confinement of both radioactive waste (from nuclear power plants, radioactive materials processing and nuclear defense artifacts) and non-radioactive waste, such as contaminated soil, asbestos, incinerator ashes, medical waste, electronic circuits, galvanic slush and waste treatment ponds.1-4 The main reason for the focus on glasses is that they are able to homogeneously accommodate a wide range of substances in their disordered structures and exhibit good tolerance in terms of changes in composition inherent to the nature of wastes. The first glasses investigated were borosilicate ones. They were extensively investigated for the immobilization of radioactive waste and are still used by countries such as France, the USA and England; the most favorable composition is based in SiO2 and borax (Na2O·2B2O3).5,6 Despite the fact that borosilicate glasses are chemically and thermally stable materials for long periods, they require relatively high encapsulating and processing temperatures (1200-1500 ºC). This requirement is, perhaps, the main disadvantage in using borosilicate glasses because some isotopes (e.g., 99Tc and 137Cs) and toxic metals (e.g., Pb and Cd) may volatilize at such high temperatures. Furthermore, several other elements-specifically, sulfur, chlorine, phosphorous, chromium and aluminum-may interfere with the vitrification process of borosilicate glasses,7 leading to phase separation. At present, no single type of glass that will be totally satisfactory and cost effective in the immobilization of all the different types of waste in the world exists. In the 1960s, phosphate glasses were investigated primarily because of their ability to accommodate sulfates into their structures without phase separation,8 their relatively low processing temperatures (1100-1250 ºC) compared to borosilicate glasses (1200-1500 ºC) and their relatively low softening temperature and liquid viscosity.9 The vitrification process using phosphate was developed at Brookhaven National Laboratory (USA) for the treatment of Purex waste (a mixture of nitric acid solution of fission products, residual salts from U and Pu extraction and corrosion products). Iron phosphate glasses, in particular, proved to have the potential to vitrify many nuclear wastes that undergo completely unsuitable or poorly suitable vitrification in borosilicate glasses,10 such as heavy metals, phosphates, sulfates and chromium oxides that are insoluble or chemically incompatible in the well-established borosilicate glass.11-13 The main drawback to the use of phosphate glasses is associated with their relatively low chemical resistance, which leads to relatively high leaching rates when they are exposed to humid environments.14 During the 1980s, an enhancement in the chemical resistance was observed when iron and lead were used in the glass formulation; this enhancement resulted in a reduced corrosion rate in aqueous environments and allowed the immobilization of medium- and high-activity radioactive wastes.15 Lead Iron Phosphate (LIP) glasses are processed at temperatures from 100 ºC to 250 ºC lower than the temperatures necessary to process borosilicate glasses. Furthermore, dissolution rates (in water) are three orders of magnitude lower for LIP glasses compared to those for borosilicate glasses at 90 ºC in solutions with pH levels ranging from 5 to 9.16 LIP glasses can also be employed to immobilize waste with high Na and S contents.7 Iron phosphate glasses without Pb have also been investigated in the immobilization of spent nuclear fuels and nuclear wastes containing 15% P2O5 by mass.17 New formulations based on iron phosphate glasses have been developed for the immobilization of low- and high-activity radioactive wastes as monoliths.18 With respect to heavy metals, the literature contains a much smaller number of works19 and, apparently, none of them involves phosphate glasses. In university environments, heavy metals are common waste residues from educational and research chemical laboratories. Their final destination is, generally, chemical landfills; however, leaching is a risk to the environment. Again, iron phosphate glasses can be used to immobilize heavy metal wastes because they can vitrify small amounts of unspecified wastes and exhibit good contention capability and good chemical durability, as previously mentioned. Currently, the management of small-scale heavy-metals waste generally involves storage, incineration, or landfill disposal because the generated amount is too small to justify any commercial use and the unspecified composition discourages its application in new materials. Incineration is being criticized worldwide because it results in the production of hazardous volatiles and ashes;20 the emissions from incineration facilities includes Pb, Hg and Cd; however, most of the metals are retained as fly and bottom ashes that end up in landfills or are eventually used as aggregates.21 Landfill disposal poses a medium-and long-term risk of water and soil contamination. In this work, the inertization of heavy-metals waste in a glass matrix was considered as a route to help in preventing the environment contamination. The wastes were used as collected from a laboratory reservoir and no attempts were made to address the effect of specific landfill chemical characteristics. Instead, this work aims to address the following issues:

The experiments conducted to answer these questions and the conclusions to which they led are discussed in the following sections.

EXPERIMENTAL Wastes were originally collected from the laboratories of the Institute of Chemistry of the University of Sao Paulo. The waste dispersion in water was treated with NaOH and the metals were separated as hydroxides by filtration through paper. At this point, some metals were still present at high concentrations in the filtrate because they formed soluble hydroxo complexes with OH-; thus, a secondary treatment with HCl was performed until the pH of the filtrate was 8, followed by a second filtration. The solids collected on the filter paper were calcined at 600 ºC for 4 h. The solid residue was analyzed by ICP-AES (metals), elemental analysis (%CHN) and flame photometry (Na+). The filtrate was analyzed by ICP-AES to ensure the efficiency of the separation process. Glasses were prepared by mixing Fe2O3 and P2O5 (4:6 by mass) with previously defined amounts of residues to a final concentration of 5%, 10%, 15%, 20%, 26%, 30%, 33%, 40% and 50% (mass %). Each mixture was placed in an Al2O3 crucible and heated in a Lindberg-Blue M furnace at 10 ºC min-1 to 1250 ºC and was maintained at this temperature for 1.5 h. The liquid was then poured into a stainless steel mold pre-heated to 520 ºC, maintained at this temperature for 2 h and then allowed to cool according to the furnace's thermal inertia. The non-crystallized glasses (5 to 26%) were cut, polished and measured with a micrometer to determine their surface area. The blocks (1 × 1 × 0.3 cm3) were then weighed (Mettler Toledo, ±0.00001 g) and the leaching experiments were performed in distilled water using a round-bottom flask fitted with a glass condenser. The reflux temperature was 90 ºC and dissolution rates were monitored for 14 d; the measurements were performed at the 1st, 3rd, 7th and 14th days, when the samples were removed from the extractor, dried at 90 ºC in air and weighed. Samples were analyzed as prepared (glass blocks) or after being milled (Fritsch Pulverisette vibratory micro mill). Powders were analyzed by X-ray diffractometry (XRD) and Fourier Transform Infrared (FTIR) and Raman spectroscopies. Raman spectroscopy was also performed on the glass blocks, which were also investigated using X-ray fluorescence energy-dispersive spectroscopy (EDS). XRD patterns were obtained using a Bruker Advance model D8; the powdered glass samples were pressed into a glass support for the analyses. FTIR spectra were collected on a Bomem MB100 Arid Zone fitted with a single-bounce ATR accessory (Golden Gate, Specac). Raman spectra were obtained using a Renishaw Raman microscope (System 3000) fitted with a Peltier-cooled CCD detector (Wright, 600 × 400 pixels) and using a metallurgical microscope (Olympus BH2-UMA). The 632.8-nm line of a He-Ne laser (Spectra Physics, model 127) was used and the laser power at the sample was typically 2.0 mW. As previously mentioned, the samples were studied as a powder and eventually as small glass blocks in the case of samples that were also characterized by SEM-EDS. SEM-EDS analysis was performed on a Philips model XL-30 scanning electron microscope.

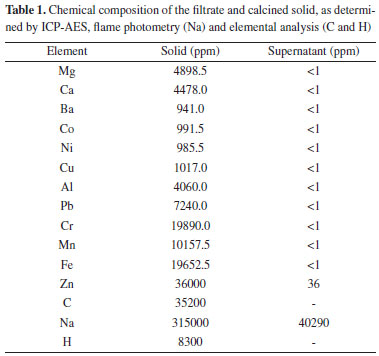

RESULTS AND DISCUSSION The filtrate and the calcined solid were analyzed by ICP to ensure the efficiency of the separation procedure (Table 1).

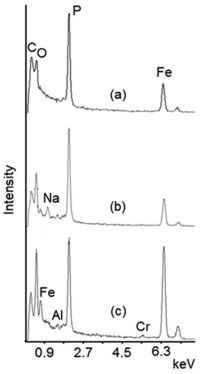

CHN and Na+ analyses of the solid were performed to verify their relative contributions, especially that of carbon from the filter-paper ashes. According to Table 1, the separation procedure proved to be adequate for the removal of the heavy metals in the filtrate to an acceptable concentration. If necessary, the separation could be improved through slight modifications, such as a better pH control and vacuum filtration because a relatively high Zn concentration (36 ppm) is likely to arise from the formation of soluble metal complexes. The final filtrate still contained some dispersed material. The EDS spectra of samples with and without wastes are show in Figures 1a and 1b, respectively, whereas in Figure 1c it is shown the spectrum from the glass sample after leaching (14 d). As evident in Figures 1b and 1c, the ratio of the peak intensities corresponding to P and Fe (IP/IFe) decreases after leaching, indicating that the leaching rate for P was greater than that for Fe. This result was expected because the initial step in the corrosion of the glass involves the release of alkaline metals to the solution and, as the leaching proceeds, the glass outer layers become richer in the less-soluble metals such as iron and chromium. Accordingly, a careful inspection of Figure 1 reveals that the peak assigned to sodium in Figure 1b was not present in Figure 1c (leached glass), whereas Cr was observed on the glass surface after leaching.

Figure 1. EDS spectra: (a) IP glass without wastes; (b) IP glass with wastes (30% by mass); (c) same as in (b) but after leaching

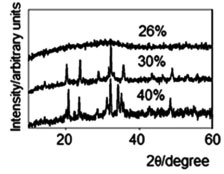

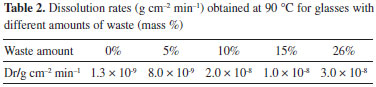

The glasses were subsequently analyzed by XRD (Figure 2) to detect the possible presence of crystalline phases formed during the slow cooling of the molten mixture; such phases give rise to sharp peaks in the diffraction pattern, whereas the pattern of the vitreous phase shows only a broad halo. Although crystalline phases are also able to accommodate waste, their performance has been demonstrated to be inferior to that of glasses.22 Dissolution rates were also measured for the non-crystallized formulations (from 5 to 26%); the obtained values are reported in Table 2.

Figure 2. XRD patterns of powdered glasses with waste (26%, 30% and 40% by mass)

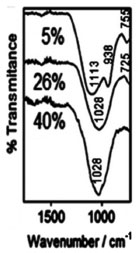

Compared with soda-silicate glasses, iron phosphate glasses exhibit better chemical durability, as shown in Table 2. The dissolution rate increases with an increase in the amount of incorporated metal; however, the rate appears to reach a plateau for concentrations greater than 10% (close to 10-8 g cm-2 min-1). Furthermore, the amount of residue that can be accommodated in the glass structure is substantially greater, as demonstrated by the XRD results (Figure 2). With respect to the XRD patterns (only the 26%, 30% and 40% compositions are shown in Figure 2), a crystalline phase was clearly observed for glasses with a residue concentration of 30% or greater. In addition, the patterns for the 30% and 40% glasses are not similar, reflecting the fact that the complex composition of the residue leads to different crystalline phases as the concentration increases. For the same reason, the nature of each crystalline phase could not be determined; vibrational spectroscopy (FTIR and Raman) was therefore used to structurally characterize the crystallized and non-crystallized glasses. As previously mentioned, the FTIR spectra were obtained from powdered glasses using a single-bounce ATR accessory. In Figure 3, the spectrum of the 5%, 26% and 40% glasses are shown (the spectra of the 0% and 5% glasses are similar) and the position of the main bands are indicated. The FTIR spectrum of the 5% glass exhibits main features at 755, 938 and 1113 cm-1; these peaks shifted when the waste amount was increased to 26% (725 and 1028 cm-1) and 40% (982 cm-1 (shoulder) and 1028 cm-1).

Figure 3. FTIR spectra of the powdered glasses containing 5%, 26% and 40% (by mass) of waste

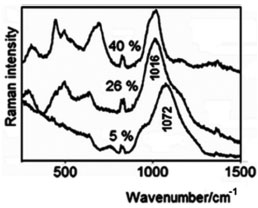

Major features are observed in the 900-1500 cm-1 range, where linear deformations of the P-O bonds are expected. Vibrational spectroscopy is a short-range technique and the reported spectra clearly show that the phosphate groups are affected by the incorporation of heavy metals; however, no further information could be obtained because of the broadness of the bands. Raman spectroscopy was, therefore, used to assess the effect of the metal ions on the glass structure. Figure 4 shows the Raman spectra obtained for the same glasses reported in Figure 3, with the positions of the main bands indicated. The Raman spectrum of the glass containing no waste is similar to the 5% spectrum and was consequently not included in the figure. The most significant bands appear at 949, 1072 and 1180 cm-1 (5%), 1016 and 1163 cm-1 (26%) and 445, 497, 691 and 1017 cm-1 (40%).

Figure 4. Raman spectra (λ0 = 632.8 nm) of the powdered glasses containing 5%, 26% and 40% (by mass) of waste; the narrow and weak feature at ca. 800 cm-1 corresponds to plasma lines from the He-Ne laser

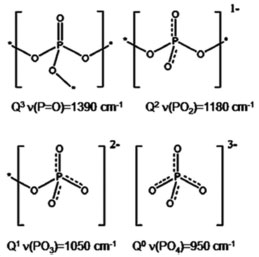

Because a Raman microscope was used, it was possible to ascertain that the samples were chemically homogeneous at the micrometric scale by comparing the spectra obtained at different spots. The presence of bands in the 300-700 cm-1 region in the 26% glass spectrum suggests the formation of discrete units involving the incorporated heavy metals, although without the long-range arrangement necessary to characterize a crystalline phase; this behavior is characteristic of encapsulation or localized glass network depolymerization. Other bands are observed in the 40% spectrum and the smaller bandwidth demonstrates that phases with greater crystallinity were formed, as indicated by their diffraction patterns (Figure 2). Another important aspect to be considered in the characterization of the glass structures by vibrational spectroscopy is the broad feature in the 900-1300 cm-1 range. In the spectra of the low-concentration glasses, this feature consists of an envelope with (at least) three components (949, 1072 and 1180 cm-1), with the most intense band observed at 1072 cm-1. When the residue concentration was increased to 26%, the 1072 cm-1 and 1180 cm-1 bands were downshifted to 1016 and 1163 cm-1, respectively. The structure of such iron phosphate glass can be described using the Qi terminology, which represents the tetrahedra formed by the P-O bonds in terms of the number of bridging oxygen atoms per tetrahedron,23 as shown in Figure 5, where the most significant Raman band for each Qi structure is presented.

Figure 5. Phosphate structure in the glasses, as defined by the Qi terminology (according to reference 23)

The position and relative intensities of the three bands observed in the spectrum of the 5% glass is typical of a glass with predominance of Q1 units. With increasing residue incorporation, the number of bridging oxygens decreases as a consequence of specific chemical interactions, leading to the shifts in band positions and changes in band intensities observed in the spectrum of the 26% glass. Notably, the residue also contains Na, which is known to break up the glass network, resulting in more singly-bonded oxygen atoms. Thus, the spectral shift is compatible with a decrease in the bond order due to the decrease in the number of bridging oxygen atoms. The same behavior can be inferred from the FTIR-ATR spectra, although the effect is not as clear as that in the Raman spectra because of the greater band widths.

CONCLUSIONS The results reported here indicate that iron phosphate glasses exhibit at least the same heavy-metal residue loading as borosilicate glass, with the advantage of lower processing temperatures. With respect to the effects of releasing the metals into the environment, leaching is a very important parameter in evaluating the performance of a glass; the dissolution rates measured for the several residue loadings are comparable to those reported for soda silicate glasses. Iron phosphate glass thus proved to be a viable option for the inertization of heavy-metal residues produced on a small scale, such as in undergraduate laboratories.

ACKNOWLEDGEMENTS The authors wish to express their gratitude to CNPq and Fapesp for financial support, to José Mario Prision, Luciana Ghussn and Frank Ferrer Sene for their assistance with the preparation of the glasses and to Marcel Serrana for the flame photometry analysis.

REFERENCES 1. Scarinci, G.; Brustain, G.; Barbieri, L.; Corradi, A.; Lancellotti, I.; Colombo, P.; Hreglich, S.; Dall'Igna, R.; J. Eur. Ceram. Soc. 2000, 20, 2485. 2. Barbieri, L.; Bonamartini, A. C.; Lancellotti, I.; J. Eur. Ceram. Soc. 2000, 20, 2477. 3. Ferraris, M.; Salvo, M.; Smeacetto, F.; Augier, L.; Barbieri, L.; Corradi, A.; Lancellotti, I.; J. Eur. Ceram. Soc. 2001, 21, 453. 4. Cimdins, R.; Rozenstrauha, I.; Berzina, L.; Bossert, J.; Bücker, M.; Resour., Conserv. Recycl. 2000, 29, 285. 5. Grover, J. R.; Radioact. Waste Manage. 1980, 1, 1. 6. Donald, I. W.; Meltcalfe, B. L.; Taylor, R. N. J.; J. Mater. Sci. 1997, 32, 5851. 7. Bingham, P. A.; Hand, R. J.; Mat. Res. Bull. 2008, 43, 1679. 8. Bingham, P. A.; Hand. R. J.; Hannant, O. M.; Forder, S. D.; Kilcoyne, S. H.; J. Non-Cryst. Solids 2009, 355, 1526. 9. Tuthill, E. J.; Weth, G. G.; Emma, L. C.; Strickland, G.; Hatch, L. P. In Proc. Symp. Solidification and Long-Term Storage of Highly Radioactive Wastes; Reagan, W. H., ed.; The Atomic Energy Commission, 1966, p 139-168. 10. Mesko, M. G.; Day, D. E.; J. Nucl. Mater. 1999, 273, 27. 11. Lambert, S. L.; Kim, D. S.; Tank Waste Remediation System High-Level Waste Feed Processability Assessment Report, PNNL #WHC-SP-1143, Washington, 1996. Disponível em http://rkc.pnl.gov/docs/files/webviewable-WHC-SD-WM-TI--768.pdf, acessada em Abril 2013. 12. Perez Jr., J. M.; Bickford, D. F.; Day, D. E.; Kim, D. S.; Lambert, S. L.; Marra, S. L.; Peeler, D. K.; Strachan, D. M.; Triplett, M. B.; Vienna, J. D.; Wittman, R.S.; High-Level Waste Melter Study Report, PNNL-13582, Washington, 2001. Disponível em http://rkc.pnl.gov/docs/files/webviewable-PNNL-13582.pdf, acessada em Junho 2014. 13. Day, D. E.; Wu, Z.; Ray, C.; Hrna, P.; J.Non-Cryst. Solids 1998, 241, 1. 14. Jantzen, C. M.; Advances in Ceramics (special issue), Nucl. Waste Manage. II 1986, 20, 157. 15. Sales, B. C.; Boatner, L. A.; Science 1984, 226, 45. 16. Cao, H.; Adams, J. W.; Kalb, P. D.; Low Temperature Glasses for Hanford Tank Wastes, Brookhaven National Laboratory, Formal report BNL-52595, N. York, 1995. Disponível em http://www.bnl.gov/isd/documents/21660.pdf, acessada em Junho 2014. 17. Sengupta, P.; J. Hazard. Mater. 2012, 235-236, 17. 18. Cao, H.; Adams, J. W.; Kalb, P. D.; U S Patent 5,880,045 1999. 19. Nishida, T.; Seto, M.; Kubuki, S.; Miyaji, O.; Ariga, T.; Matsumoto, Y.; J. Ceram. Soc. Japan 2000, 108, 245. 20. Aranha, N.; Tese de Doutorado, Universidade de Campinas, Brasil, 1994. 21. Collivignarelli, C.; Sorlini, S.; Waste Manage. 2002, 22, 909. 22. EPA Handbook "Vitrification Technologies for Treatment of Hazardous and Radioactive Waste", EPA/625/R-92/002, 1992. 23. Brow, R. K.; J. Non-Cryst. Solids 2000, 263-264, 1. |

On-line version ISSN 1678-7064 Printed version ISSN 0100-4042

Qu�mica Nova

Publica��es da Sociedade Brasileira de Qu�mica

Caixa Postal: 26037

05513-970 S�o Paulo - SP

Tel/Fax: +55.11.3032.2299/+55.11.3814.3602

Free access