Artigo

| An alternative energy generation from charcoal produced from brazilian pine (Araucaria angustifolia (Bert.) O. Ktze) seed residues |

|

Danielle Affonso SampaioI,*; Alfredo José dos Santos JuniorII; Ananias Francisco Dias JúniorII; Roberto Carlos Costa LelisI

I. Departamento de Produtos Florestais, Universidade Federal Rural do Rio de Janeiro, Km 7 BR-465, 23890-000 Seropédica - RJ, Brasil Recebido em: 25/02/2022 *e-mail: dannisampaio@ufrrj.br The perspective is that the energy demand will grow in the coming decades worldwide. The search for renewable energy sources is urgent and necessary. Residual biomass may be a promising source of raw material for obtaining bioenergy. Thus, this research sought to evaluate the energetic and physicochemical properties of residues from the seeds of Brazilian pine (Araucaria angustifolia (Bert.) O. Ktze). The chemical analysis included the extractive, holocellulose, and Klason lignin contents. The residues were pyrolyzed according to the final temperature of each process (300 ºC - 550 ºC) and a control treatment. The proximate analysis was performed to determine the moisture content, volatile matter, ash, and fixed carbon. We determined bulk density, the higher heating value, and the net heating value. The determination of the energetic density was also calculated. The residues showed significant values in lignin and extractives. The pyrolysis treatments performed at the final temperature of 350 ºC and 400 ºC presented a higher value of gravimetric charcoal yield. The charcoal obtained at 500 ºC and 550 ºC had better energetic properties. The Brazilian pine seed residues under the pyrolysis process presented desirable energy characteristics, showing its potential for use as a raw material in bioenergy generation. INTRODUCTION The world energy matrix is concentrated on fossil fuels.1 Fossil fuels are non-renewable sources of energy and their burning releases harmful gases into the atmosphere that significantly contribute to the increase in the planet's temperature. With this concern, the Agreement signed in Paris in 2015 by more than 190 countries, including Brazil, aims to reduce the dependence of its energy matrix on non-renewable sources, by investing in alternative energy sources.2 In Brazil, the panorama is different. Although it still uses non-renewable energy, the Brazilian energy matrix is essentially composed of renewable sources.1 Renewable sources are mainly represented by hydropower and sugarcane biomass; however, charcoal is highlighted, with Brazil being the largest producer of charcoal in the world.1,3 With the Southeast as the main consumer region of this input in the Country.3 The perspective is that the energy demand will grow in the coming decades not only in Brazil but worldwide.4 Therefore, the search for raw material as an alternative energy source is urgent and necessary. The Brazilian pine (Araucaria angustifolia (Bert.) O. Ktze.) is a species of conifer that occurs naturally in the Atlantic Forest biome and is found in the Southeast (Minas Gerais, Rio de Janeiro, São Paulo) and South (Paraná, Rio Grande do Sul, Santa Catarina) regions of the Country.5 The Brazilian pine seed is a high nutritional value food.6 The seed is included in the Minimum Price Guarantee Policy for Socio-biodiversity Products (PGPM-Bio) developed by the National Supply Company - CONAB which guarantees a minimum price for the 17 main non-timber products extracted from native forest species in Brazil that help in the conservation of Brazilian Biomes.7 During the consumption of the Brazilian pine seed, its coat is discarded, generating approximately 20% of its weight in the form of residue.8 With a lignin content of about 30%,9 this forest residue can be a promising biomass option for renewable energy production since the high lignin content in biomass can contribute to higher charcoal yields.10,11 In the process of obtaining charcoal, the temperature used is an important parameter to define the quality of the charcoal produced.12 The final temperature used has effects on density, the content of volatile matter, ash, fixed carbon, and the higher heating value.13,14 Another important parameter to define the quality of charcoal is the calorific value; the higher the value of this parameter, the greater the energy contained in the fuel.15 To enable the use of biomass for the production of charcoal it must presents characteristics such as high density, high fixed carbon content, low moisture content, low content of volatile matter and ashes; and, mainly, a high heating value.16,17 In this context, the present work aims to verify the energy potential of the residues of seeds of Brazilian pine (Araucaria angustifolia), to evaluate the gravimetric charcoal yield of this forest residue, and perform the proximate analysis of charcoal produced under different pyrolysis temperatures.

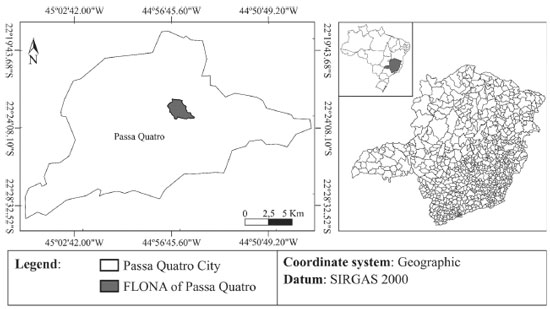

MATERIAL AND METHODS Material The seeds of Brazilian pine were obtained from plantations located in the Passa Quatro National Forest (FLONA), located in the Passa Quatro City (Minas Gerais State), geographically located at the coordinates 44° 56' 30.71" W and 22° 23' 33.90" S, 119 m a.s.l. (Figure 1). The climate classification, according to Köppen, is subtropical in altitude (Cwb), with an average annual precipitation of 1676 mm and an average annual temperature of 20 °C.18,19 The seeds were transported to the Wood Chemistry Laboratory of the Department of Forestry Products (IF-UFRRJ). Healthy seeds were peeled to separate the seed coat from the almonds. The residues of seeds (coats) were stored in an acclimatized room at 25 ºC.

Figure 1. Brazilian pine (Araucaria angustifolia) seeds collection localized in Passa Quatro National Forest, Passa Quatro City, MG, Brazil

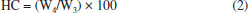

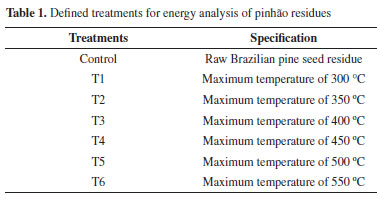

Chemical Analysis of the Brazilian pine seed residues The residues were processed in a Willey-type knife mill (Model SL 31). The milled sample was homogenized and sieved and only the particles retained in the 60 mesh sieve were used for extraction with cyclohexane, ethyl acetate, and methanol. The extraction was performed in a soxhlet type extractor, for 24 hours without interruption for each extraction.20 The extractives contents were determined according to the equation 1:  where: EC = extractives content (%); W2 = concentrated extractive (g); and W1 = dried sample (g). The contents of Holocellulose and Lignin were determined from the samples of the pinhão residues extract-free, according to Abreu et al.20 The contents of Holocellulose were determined according to the equation 2:  where: HC = holocellulose content (%); W4 = dried holocellulose residue (g); and W3 = dry weight of the extract-free sample (g). The contents of Lignin were determined according to the equation 3:  where: LC = Klason lignin content (%); W5 = dry weight of residual lignin (g); and W3 = dry weight of the extract-free sample (g). Physical-energetic Analysis of the Brazilian pine seed residues The residual seeds were dried in an oven at 105 ± 3 °C until obtaining a constant mass, later this material was submitted to a pyrolysis process, carried out in a muffle furnace. Six treatments were defined for the pyrolyzed material according to the final temperature of the process and a control treatment (Table 1).

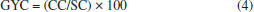

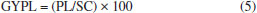

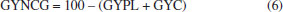

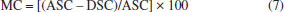

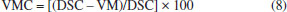

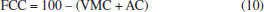

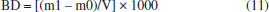

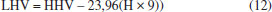

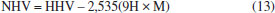

After the pyrolysis processes were carried out according to the determined treatments, the gravimetric yields of energetic products (charcoal, pyroligneous liquid, and non-condensable gases) were determined. The gravimetric yield of charcoal was determined according to the equation 4:  where: GYC = Gravimetric yield in charcoal (%); CC = Weight of the charcoal obtained (g), and SC = Initial weight of the seed coat sample (g). The gravimetric yield of pyroligneous liquid was determined according to the equation 5:  where: GYPL = Gravimetric yield in pyroligneous liquid (%); PL = Weight of the pyroligneous liquid obtained (g), and SC = Initial weight of the seed coat sample (g). The gravimetric yield of non-condensable gases was determined according to the equation 6:  where: GYNCG= Gravimetric yield on Non-condensable gases (%); GYPL = Gravimetric yield in pyroligneous liquid (%) and GYC = Gravimetric yield in charcoal (%). To determine the moisture content, volatile matter, ash, and fixed carbon of the seed residues were carried out by proximate analysis, adapting to the D1762-84 standard.21 The moisture content was determined according to the equation 7:  where: MC = moisture content (%); ASC = air-dry sample of seed coat (g); and DSC = sample of seed coat after drying at 105 °C (g). The Volatile Matter Content (VMC) was determined according to the equation 8:  where: VMC = Volatile matter content (%); DSC = sample of seed coat after drying at 105 °C (g); and VM = sample after volatile step at 950 °C (g). The Ash content (AC) was determined according to the equation 9:  where: AC = Ash Content (%); DSC = sample of seed coat after drying at 105 °C (g); and A = Weight of the residue inside the crucible (g). The Fixed carbon content of charcoal (FCC) was determined according to the equation 10:  where: FCC = Fixed Carbon Content (%); VMC = Volatile Matter Content (%) and AC = Ash Content (%). The determination of bulk density of raw seed residues and pyrolyzed seed residues was carried out by adapting the E873-72 standard.22 Calculated according to the following equation 11:  where: BD = Bulk density (kg m-3); m1 = mass of container with material (g); m0 = mass of the empty container (g); V = container volume (cm-3). The higher heating value (HHV) was obtained according to the E870-82 standard,23 using an adiabatic calorimeter (C200, IKA). The determination of the lower heating value (LHV) was carried out by adapting the standard E711-87,24 according to Equation 12:  where: LHV = lower heating value (J g-1); HHV = higher heating value (J g-1) e H =hydrogen content of the sample (%). The net heating value (NHV) was performed using the methodology suggested by Demirbas25 and assuming a value of 6% hydrogen for biomass,26 using Equation 13:  where: NHV = net heating value (kcal kg-1); HHV = higher heating value (kcal kg-1); H = hydrogen content of the sample (%) e M = moisture content on wet basis (%). The determination of the energy density was performed by adapting to the methodology suggested by Garcia et al.27 according to Equation 14:  where: ED = energetic density (Mcal m-3); NHV = net heating value (kcal kg-1) e BD = bulk density (kg m-3). Data analysis Data analysis was performed using the IBM SPSS Advanced Statistic 20.0 statistical program. The data obtained after the tests were submitted to the Shapiro-Wilk normality test, and this premise was confirmed, the homoscedasticity of the data was analyzed using the Levene test. Once these assumptions were confirmed, the analysis of variance (ANOVA) was performed following a completely randomized design (DIC) with three replications for each variable tested. After this step, the data were subjected to the multiple means comparison test using the Tukey test at a significance level of 0.05. Subsequently, the data were submitted to a matrix of correlations for the simultaneous evaluation of the association between the variables using the Pearson coefficient.

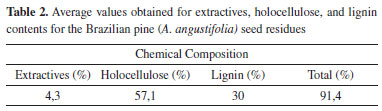

RESULTS The results obtained after the physical-chemical and energetic characterization of the Brazilian pine residues are described in the following tables. Table 2 presents the values obtained for the Chemical Composition of the Brazilian pine seed residues.

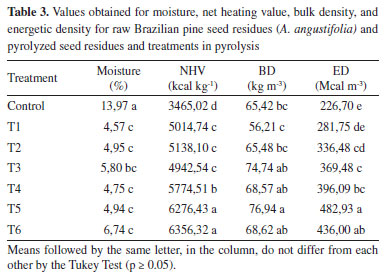

Table 3 shows the values obtained for the moisture content, net heating value, bulk density, and energetic density of the raw Brazilian pine seed residues and pyrolyzed seed residues treatment.

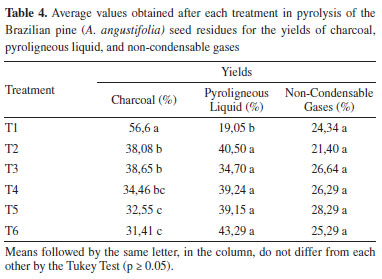

Table 4 presents the values obtained for the yields of charcoal, pyroligneous liquid, and non-condensable gases after the pyrolysis of the Brazilian pine seed residues at different temperatures.

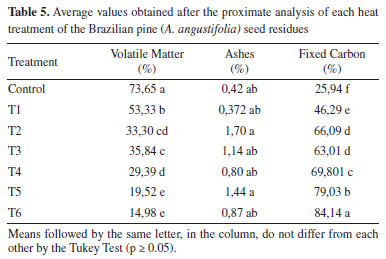

Table 5 shows the values obtained for the yields in fixed carbon, volatile matter, and ashes after the proximate analysis carried out on the charcoal obtained from the Brazilian pine seed residues in each heat treatment.

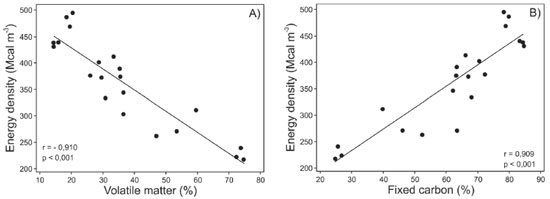

Figure 2 shows the correlation obtained between the results of proximate analysis and energy density.

Figure 2. Correlation between the results of proximate analysis and energy density. A. Negative correlation between Volatile matter (%) and Energy density (Mcal m3). B. Positive correlation between Fixed Carbon (%) and Energy density (Mcal m3)

DISCUSSION The values found in the chemical composition for the Brazilian pine seed residues are similar to those reported in previous works.15,28 Lignin is directly related to the thermal energy released by biomass.29 Higher contents of lignin and extractives are related to a higher calorific value of the material.30 For energy purposes, the moisture content is an important physical property to consider since moisture has an inverse relationship to the calorific value of biomass.31 The moisture content found for Brazilian pine seed residues is close to that reported in the literature for forest and agricultural residues with energy potential.32 The heating value is an energy property that stands out as one of the main quality parameters, as it represents the amount of energy released during the combustion of the material, being essential to discriminate its energy capacity.33 The net heating value (NHV) considers the water content of the biomass, the pyrolysis treatments T5 (500 ºC) and T6 (550 ºC) presented desirable values for energy purposes, presenting a net heating value (6276.43 6356.32 kcal kg 1) higher than that reported in the literature for different forest biomass32,34,35 and that reported for forest residues of Eucalyptus spp. and Pinus taeda;36 being then the most indicated treatments for obtaining energy. Bulk density is related to particle size; in this study, there was no difference in the pyrolysis treatments carried out from T3. This may have occurred due to the greater friability of the charcoal as the pyrolysis temperature increased, resulting in greater material compaction. Higher bulk density values are desirable, and aspects such as transport costs and energetic density are important for the economic viability of renewable energies. The energetic density represents the energy contained in a certain volume of material. In the present study, the methodology defined to assess this property used bulk density and net heating value data, as it is better approaching a practical application.27 The Pyrolysis treatments T5 (500 ºC) and T6 (550 ºC) presented the highest values. In general, the energetic density values were low, this may have been due to the bulk density values found for the Brazilian pine seed residues, which influenced the low energy density of the material. An alternative would be the densification of this raw biomass through compaction processes to increase the density of the material and, consequently, its energetic density. Energetic density values reported for compacted residual biomass corroborate the efficiency of the technique.36,37 The T1 treatment (300 ºC) showed the highest gravimetric yield in charcoal, however, at this temperature the material was not completely carbonized, which results in higher mass after the process. From the treatment T2 to T6, the pyrolysis process was complete, thus, the pyrolysis process carried out at a final temperature of 350 ºC and 400 ºC presented the highest value in charcoal yield; 38.08% and 38,65%, respectively. According to the report by the Brazilian Tree Industry,3 the main species cultivated in Brazil for energy purposes belong to the genus Eucalyptus. Eucalyptus wood presents average values of 35% in gravimetric charcoal yield at temperatures between 350 ºC - 450 ºC.3840 Of the structural elements of the Cell Wall, lignin is the most energetically stable component,41 the Brazilian pine seed residue is a material rich in guaiacyl units lignin.9,28 According to Araújo et al.11 and Santos et al.42 guaiacyl structures of lignin can increase the gravimetric yield in charcoal. As for the co-products of the pyrolysis process, the Brazilian pine seed residue presented an average value of 39% for the yield of pyroligneous liquid and an average value of 25.5% for the yield of non-condensable gases. These values are close to those reported in the literature for Eucalyptus wood.39,40 For the Brazilian pine seed residues, the highest fixed carbon content was 84.1% obtained in the T6 carbonization treatment (550 °C) followed by the T5 carbonization treatment (500 °C) with 79.03% of fixed carbon content. Fixed carbon expresses the amount of solid carbon in the material at the end of the pyrolysis process,43 and is directly related to the lignin content of the biomass and the pyrolysis temperature.13,14 Thus, for energy purposes, higher levels of fixed carbon are more desirable. The value determined for the residues of Brazilian pine seed is higher than that reported in the literature for the most diverse sources of residual biomass. Forest biomass showed average fixed carbon content of 66.57% at a temperature of 500 ºC in the pyrolysis process.44 Wood residues from tropical species had an average fixed carbon content of 35.38% for carbonization at 500 ºC.14 Ash and volatile matter corresponds to the residual material from the thermal decomposition of the material in the pyrolysis process, the average values obtained for the Brazilian pine seed residues are close to the values described in the literature for native species14,44 and Eucalyptus.39,42 Ashes do not contribute to the process and therefore it is not desirable to have high contents of these components;45 as for the content of volatile matters, species with lower levels provided better energy yield.40,44 The fixed carbon content of the Brazilian pine residue showed a positive correlation with the energy density, while the volatile matter content had an inverse trend. This behavior can be explained by the concentration of fixed carbon that occurs when the final pyrolysis temperature increases, while more chemical bonds are broken, which reduces the volatile matter content in charcoal.43 The process of carbon concentration and elimination of volatile matter increases the thermal stability of charcoal, increasing its energy density.30

FINAL CONSIDERATIONS The Brazilian pine seed residues presented values of heating value and fixed carbon close to or even higher than those reported in the literature for different agroforestry residues and for species traditionally used to obtain energy. The values of ash content and volatile matter content obtained are within those reported in the literature. Bulk density values found influenced the low energy density of the material, thus it is recommended to densify this biomass through compaction processes, to increase the density of the material and, consequently, its energy density. In general, the Brazilian pine seed residues under the pyrolysis process presented desirable energy characteristics, showing their potential for use as a raw material in bioenergy generation mainly in the Southeast and South of the country, where this species naturally occurs, enabling its insertion into the local economy.

ACKNOWLEDGMENTS The authors would like to thank G. F. Mayrinck, A. C. Lindolfo, Á. M. da Silva and J. C. Batista for valuable collaboration in the development of energy analysis.

FUNDING SOURCES This study was financed in part by the Coordination for the Improvement of Higher Education Personnel - Brasil (CAPES) Finance Code 001. It was also supported by the National Council for Scientific and Technological Development (CNPQ) and the Carlos Chagas Filho Foundation for Supporting Research in the State of Rio de Janeiro (FAPERJ).

REFERENCES 1. EPE - Energy Research Company, Brazilian Energy Balance 2020 Year 2019, EPE: Rio de Janeiro, 292 p., 2020, available at https://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/balanco-energetico-nacional-ben, accessed July 2022. 2. UNFCCC - United Nations Framework Convention on Climate Change, The Paris Agreement, 2015, available at https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement, accessed July 2022. 3. IBÁ - Brazilian Tree Industry Report, 176p., 2021, available at https://iba.org/datafiles/publicacoes/relatorios/relatorioiba2021-compactado.pdf?utm_source=akna&utm_medium=email&utm_campaign=Iba-lanca-Relatorio-Anual-2021, accessed July 2022. 4. IEA - International Energy Agency, World Energy Outlook, 2020, available at https://www.iea.org/topics/world-energy-outlook, accessed in July 2022. 5. Iganci, J. R. V.; Dorneles, M. P.; Araucariaceae in Flora do Brasil 2020, Botanical Garden: Rio de Janeiro, 2020, available at http://floradobrasil.jbrj.gov.br/reflora/floradobrasil/FB33971, accessed July 2022. 6. CONAB - Brazilian National Supply Company, Boletim da Sociobiodiversidade 2019, 3, 1, available at https://www.conab.gov.br/info-agro/analises-do-mercado-agropecuario-e-extrativista/boletim-da-sociobiodiversidade/boletim-sociobio, accessed July 2022. 7. Ministry of Agriculture Livestock and Supply - MAPA, Bioeconomia da floresta: a conjuntura da produção florestal não madeireira no Brasil. Brazilian Forest Service: Brasília, 84 p. 2019, available at https://www.florestal.gov.br/publicacoes/1727-bioeconomia-da-floresta-conjuntura-da-producao-florestal-nao-madeireira-no-brasil, accessed July 2022. 8. Conforti, P. A.; Lupano, C. E.; Starch-Starke 2007, 59, 284. [Crossref] 9. Sampaio, D. A.; Abreu, H. S.; Silva, L. D. S. A.; Ibanez, C. M.; Bosque 2016, 37, 549. [Crossref] 10. Pereira, B. L C.; Carneiro, A. C. O.; Carvalho, A. M. M. L.; Colodette, J. L.; Oliveira, A. C.; Fontes, M. P. F.; BioResources 2013b, 8, 4574. 11. Araújo, A. C. C.; Trugilho, P. F.; Napoli, A.; Braga, P. P. C.; Lima, R. V.; Protásio, T. P.; Scientia Forestalis 2016, 44, 405. [Crossref] 12. Couto, A. M.; Trugilho, P. F.; Napoli, A.; Lima, J. T.; Silva, J. R. M.; Protásio, T. P.; Scientia Forestalis 2015, 43, 817. [Crossref] 13. Araújo, A. C. C.; Costa, L. J.; Braga, P. P. C.; Guimarães Neto, R. M.; Rocha, M. F. V.; Trugilho, P. F.; Pesquisa Florestal Brasileira 2018, 38, 1. [Crossref] 14. Silva, R. C.; Marchesan, R.; Fonseca, M. R.; Dias, A. C. C.; Viana, L. C.; Pesquisa Florestal Brasileira 2018, 38, 1. [Crossref] 15. Diez, O. A.; Cárdenas, G. J.; Mentz, L. F.; Rev. Ind. Agric. Tucuman 2010, 87, 29. 16. Monteiro, M. M.; Neto, P. N.; Martins, K. B. S.; Melo, J. L. D.; Medeiros, N. C. G.; Junior, C. M. P.; Agropecuária Científica do Semiárido 2019, 15, 176. [Crossref] 17. Oliveira, A. C.; Carneiro, A. C. O.; Vital, B. R.; Almeida, W.; Pereira, B. L. C.; Cardoso, M. T.; Scientia Forestalis 2010, 38, 431. [Crossref] 18. Alvares, C. A.; Stape, J. L.; Sentelhas, P. C.; Gonçalves, J. L. M.; Sparovek, G.; Meteorol. Z. 2013, 22, 711. [Crossref] 19. INMET - National Institute of Meteorology, Meteorological Database, 2021, available at https://bdmep.inmet.gov.br/, accessed July 2022 20. Abreu, H. S.; Carvalho, A. M.; Monteiro, M. B. O.; Pereira, R. P. W.; Silva, H. R.; Souza, K. C. A.; Amparado, K. F.; Chalita, D. B.; Floresta e Ambiente 2006, 20, available at https://app.periodikos.com.br/journal/stfloram/article/587fb4d30e88251a6ab65ffe, accessed July 2022. 21. ASTM - American Society for Testing and Material, Standard Test Method for Chemical Analysis of Wood Charcoal D1762-84, 2007, available at https://www.academia.edu/33739293/Standard_Test_Method_for_Chemical_Analysis_of_Wood_Charcoal_1, accessed July 2022. 22. ASTM - American Society for Testing and Material, Standard Test Method for Bulk Density of Densified Particulate Biomass Fuels E873-72, 2019, available at https://www.astm.org/e0873-82r19.html, accessed July 2022. 23. ASTM - American Society for Testing and Material, Standard Test Methods for Analysis of Wood Fuels E870-82, 2019, available at http://www.astm.org/cgi-bin/resolver.cgi?E870, accessed July 2022. 24. ASTM - American Society for Testing And Material, Standard Test Methods for Gross Calorific Value of Refused-Derived Fuel by the Bomb Calorimeter E711-87, 2004, available at http://www.astm.org/cgi-bin/resolver.cgi?E711, accessed July 2022. 25. Dermibas, A.; Energy Sources, Part A 2007, 29, 649. [Crossref] 26. Klock, U.; Andrade, A. S.; Química da Madeira, Universidade Federal do Paraná: Curitiba, 2013, 87 p. 27. Garcia, P. D.; Caraschi, J. C.; Ventorim, G.; Vieira, F. H. A.; Protásio, T. P.; Renewable Energy 2019, 139, 796. [Crossref] 28. Sampaio, D. A.; Garcia, R. A.; Lima, H. R. P.; Floresta e Ambiente 2019, 26 2:e20170867. [Crossref] 29. Telmo, C.; Lousada, J.; Biomass Bioenergy 2011, 35, 1663. [Crossref] 30. Protásio, T. P.; Lima, M. D. R.; Scatolino, M. V.; Silva, A. B.; Figueiredo, I. C. R.; Hein, P. R. G.; Trugilho, P. F.; Renewable Energy 2021, 164, 34. 31. Furtado, T. S.; Ferreira, J. C.; Brand, M. A.; Neves, M. D.; Revista Árvore 2012, 36, 577. [Crossref] 32. Dionizio, A. F.; Vale, A. T.; Moreira, A. C. O.; Galvão, L. G. O.; Chaves, B. S.; Costa, M. A.; Revista de Ciências Agrárias 2019, 2, 528. [Crossref 33. Carneiro, A. C. O.; Castro, A. F. N. M.; Castro R. V. O.; Santos, R. C.; Ferreira, L. P.; Damásio R. A. P.; Vital, B. R.; Revista Árvore 2014, 38, 375. [Crossref] 34. Freitas, A. J.; Costa, A. C. S.; Oliveira, A. C.; Pereira, B. L. C.; Rocha, M. F. V.; Carneiro, A. C. O.; Nativa 2016, 4, 380. [Crossref] 35. Souza, F. de; Vale, A. T. do.; Pesquisa Florestal Brasileira 2016, 36, 405. [Crossref] 36. Saccol, A. F. O.; Welter, C. A.; Rosa, R. C.; Coldebella, R.; Longhi, S. L.; Farias, J. A.; Pedrazzi, C.; Matéria 2020, 25, e-12634. [Crossref] 37. Schneid, E.; Adv Forestry Sci 2020, 7, 1203. [Crossref] 38. Protásio, T. D. P.; Couto, A. M.; Trugilho, P. F.; Junior, J. B. G.; Junior, P. H. de. L.; SILVA, M. M. O.; Scientia Forestalis 2015, 43 801. [Crossref] 39. Soares, V. C.; Bianchi, M. L.; Trugilho, P. F.; Höfler, J.; Pereira, A. J.; Cerne 2015, 21, 191. [Crossref] 40. Jesus, M. S.; Costa, L. J.; Ferreira, J. C.; Freitas, F. P.; Santos, L. C.; Rocha, M. F. V.; Floresta 2017, 47, 11. [Crossref] 41. Dermibas, A.; Energy Sources, Part A 2017, 39, 592. [Crossref] 42. Santos, R. C.; Carneiro, A. C. O.; Vital, B. R.; Castro, R. V. O.; Vidaurre, G. B.; Trugilho, P. F.; Castro, A. F. N. M.; Ciência Florestal 2016, 26, 657. [Crossref] 43. Cai, J.; He, Y.; Yu, X. Banks, S. W.; Yang, Y.; Zhang, X.; Yu, Y.; Liu, R.; Bridgwater, A. V.; Renewable Sustainable Energy Rev. 2017, 76, 309. [Crossref] 44. Fortaleza, A. P.; Filho, J. J. N.; Ceretta, R. P. S.; Barros, D. S.; Silva, S. S.; Ciência Florestal 2019, 29, 1436. [Crossref] 45. Lins, T. R. S.; Braz, R. L.; Junior, C. G. C. S.; Correia, H. T. V.; Silva, T. C.; Walter, L. S.; Biofix Scientific Journal 2020, 5, 39. [Crossref] |

On-line version ISSN 1678-7064 Printed version ISSN 0100-4042

Qu�mica Nova

Publica��es da Sociedade Brasileira de Qu�mica

Caixa Postal: 26037

05513-970 S�o Paulo - SP

Tel/Fax: +55.11.3032.2299/+55.11.3814.3602

Free access